|

|

Post by auburnaviator on Feb 25, 2011 20:58:51 GMT -5

Are you doing 8 lug or 5 lug?

|

|

|

|

Post by rccolacc on Feb 28, 2011 10:50:41 GMT -5

The stock axles are 6 lug pretty sure. I'm keeping it whatever it is...

|

|

|

|

Post by rccolacc on Mar 13, 2011 13:55:26 GMT -5

|

|

|

|

Post by rccolacc on Mar 13, 2011 14:01:14 GMT -5

Finally got all the hub parts in and I was able to put the outers all together:   Started on the longarms--   Plug welded the 1" coupling nuts in the arms:   Coped the ends to accept the bushing rings:   Jig for setting the upper link mounts:  Productive weekend. Until next time... -RC |

|

|

|

Post by rccolacc on Mar 13, 2011 17:37:26 GMT -5

Stick a fork in it. The longarms are done.   Plug welded the coupling nuts in the tube:  Upper link mounts are just tacked. They may need to be at a different angle to not hit the frame. I'll find out when I put them on.  Pressed (beat) the bushings in the axle. What a mess those are to put on...  Until next time... |

|

|

|

Post by auburnaviator on Mar 13, 2011 20:57:21 GMT -5

Looks outstanding!!! Give me a call and we'll talk about getting my 8.8 set up this week. I want to come by and see all of this in person.

|

|

|

|

Post by rccolacc on Mar 16, 2011 10:20:13 GMT -5

Lesson learned on the plug welds on nuts--

Make sure you leave a bolt or something in the nut before you weld it. I tried the plug weld a few different ways (with a bolt in and without) and it works a lot better if the bolt is in. It makes sense when you think about it, but the threads deform a little bit when you put that much heat on the outside of the nut. If you leave the bolt in, it keeps that deforming to a minimum and also the bolt acts as a heat sink for the nut. Leaving the bolt in until everything has cooled makes sure the threads don't deform more than the bolt will accept.

I plug welded the nuts with the bolts in and the end links work really well threading in and out. No deformation is really noticed.

-RC

|

|

|

|

Post by rccolacc on Mar 22, 2011 15:42:42 GMT -5

|

|

|

|

Post by rccolacc on Mar 29, 2011 18:32:48 GMT -5

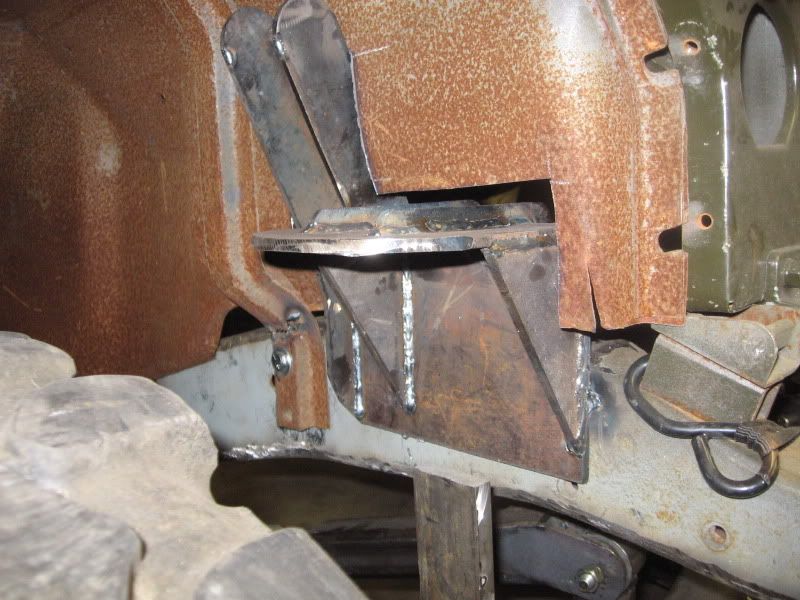

Straight up on the UCA mounts was too far to the other side:  The UCA barrels have 33* or something of movement, but when you put it on the mounts, the barrel hits the mounts before it gets to the 33*. I decided to just mount the mounts to the UCA and weld them where they fall.  Copy  All done   -RC |

|

|

|

Post by auburnaviator on Mar 29, 2011 20:21:52 GMT -5

Looks good RC. That angle shouldn't be an issue at all, the joints looked like they filled in nicely with weld so they'll be plenty strong.

|

|

|

|

Post by rccolacc on Apr 8, 2011 9:24:09 GMT -5

Played with the axle again. I moved it back some. Added a trackbar ratchet strap to center it. That will work right?   Tacked up the coil/spring mounts. I need to add a few gussets and drill the shock mount hole, but I think it looks pretty good.   The parts for it were plasma cut-- I didn't use the grinder on them. Too complicated. Until next time... -RC |

|

|

|

Post by rccolacc on Apr 12, 2011 9:26:16 GMT -5

Got the springs mounted last night:    Put the rear axle where it's going to go and just tack welded it to the frame. Put all the tires on it:  The frame seems pretty high, so that's why the spring mounts aren't fully welded. It should sag about 2" more with the engine and things in it. We'll see. -RC |

|

|

|

Post by rccolacc on Apr 17, 2011 21:30:06 GMT -5

Turned the M38 around in the shop. Cut the fenders and tried them out:    This is what it will look like at ride height:  SOON!  Went ahead and welded the spring mounts. I'll drill the holes and weld it to the frame later:  |

|

|

|

Post by auburnaviator on Apr 20, 2011 17:06:05 GMT -5

Looks good RC. I agree that it looks to high with the springs in but once you pulled them and lowered it down to ride height it looked lots better.

|

|

|

|

Post by broncocraigellis on Apr 23, 2011 17:46:41 GMT -5

Looks like it's coming together.

|

|